The Advantages and Disadvantages of PVC Reflective Tape

MAX Reflective Accessories Design Director

If you are in the market for reflective tape, especially PVC reflective tape, it is important to understand the advantages and disadvantages of this product. As a supplier of PVC reflective tape, I have witnessed firsthand how it performs in various conditions and applications.

Let’s analyze its main advantages and disadvantages so that you can make an informed choice or better introduce this product to your customers.

Advantages of PVC reflective tape

High Reflectivity

One of the most significant selling points of PVC reflective tape is its high reflectivity. This tape can reflect light at levels ranging from 15 to 1200 candela per lux per square meter (CPL).

Different colors have different reflectivity coefficients, with white and fluorescent yellow being the most reflective, reaching reflectivity levels of up to 700-1200 CPL. This means that when light hits the tape, it bounces back brightly, making it highly visible in low-light or nighttime conditions.

Cold resistance

PVC reflective tape is durable in cold weather conditions. Under lab conditions, it doesn’t crack at temperatures as low as -5℃ and can even withstand temperatures as low as -30℃.

This makes it a reliable choice for outdoor use in colder climates where other materials might become brittle or fail.

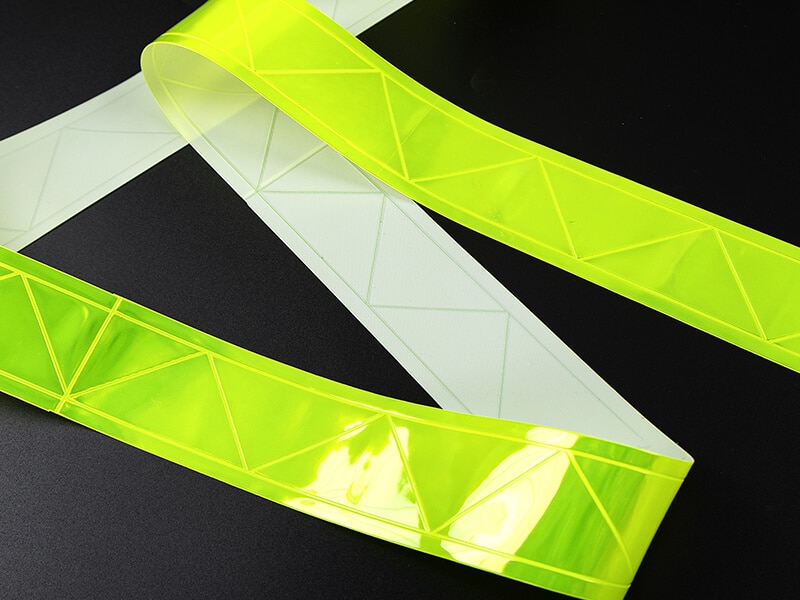

Washable

Another practical advantage is that PVC reflective tape is washable. According to standards such as EN ISO 20471:2013/1:2016, which cover retroreflective materials, it’s recommended to sew sealing strips onto clothing or fabrics to maintain retroreflection after washing.

This means you can use PVC reflective tape on workwear or safety vests that need regular cleaning without losing their reflective properties.

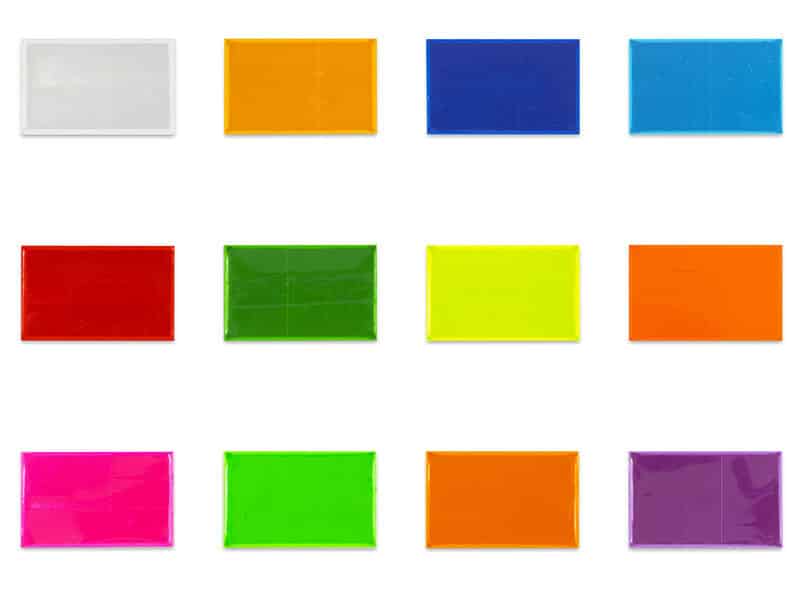

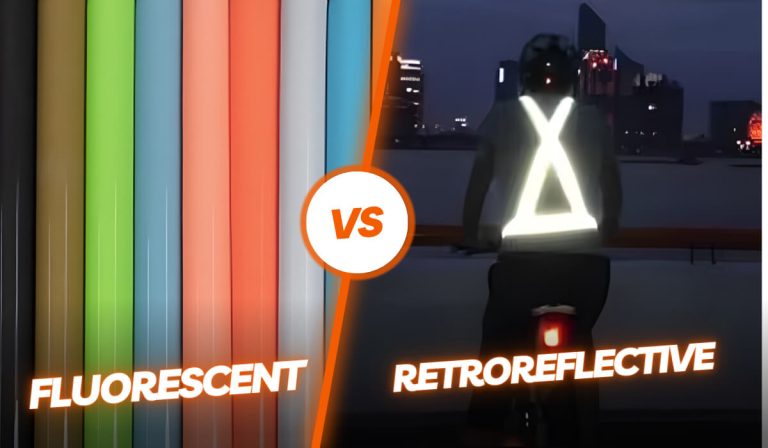

Variety of colors

PVC reflective tape is available in various colors, and custom colors can also be created upon request.

Keep in mind, though, that the darker the color, the lower the reflectivity. So if maximum visibility is your goal, lighter colors like white or fluorescent yellow are better choices.

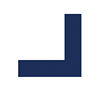

Texture and visual effects

The surface of PVC reflective tape is smooth and shiny, enhancing its reflective quality.

This soft texture also gives it a neat, professional look when applied to clothing, equipment, or vehicles.

Attention-grabbing and better warning effect

Colors like fluorescent yellow or fluorescent orange are especially eye-catching.

These bright colors not only reflect light well but also stand out during the day, making them excellent for warning signs, safety vests, and other applications where attracting attention is crucial. They tend to be more noticeable than ordinary silver or gray reflective strips.

Disadvantages of PVC reflective tape

Price variation based on reflectivity

The price of PVC reflective tape varies significantly depending on its reflectivity.

Higher reflectivity means higher cost, with prices ranging from about US$0.9 per meter to US$5 per meter or even more. This can be a consideration if you’re working with a tight budget or need large quantities.

Shape recovery after folding

If you sew PVC reflective tape onto clothing or vests, it may take a short time to return to its original shape after being folded.

This means that if the garment is folded or compressed for a while, the tape might temporarily crease or deform, which could affect its appearance or reflective performance until it flattens out again.

Color mixing risk when folding

When using colored PVC reflective tape on reflective vests, it’s essential to place a layer of isolation paper between folds.

This prevents color mixing or transfer, which can happen due to heat, pressure, or moisture. Without this precaution, the colors might bleed or stain each other, reducing the quality and look of the product.

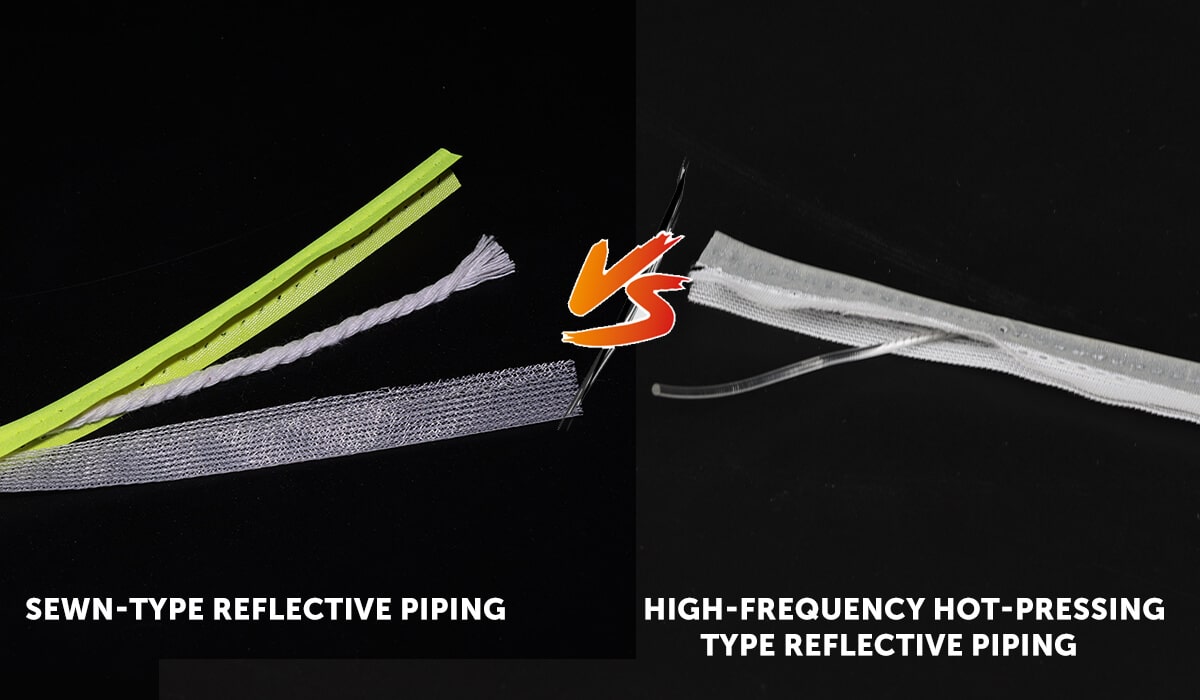

Sewing considerations

Sewing PVC reflective tape requires some care. The stitch density should be controlled—ideally, six stitches within 2 cm—to avoid edge breakage. If the stitches are too far apart or uneven, the edges of the tape can fray or peel, reducing its durability and safety.

A Guide to Handling and Using PVC Reflective Tape

Summary Table

| Aspect | Advantages | Disadvantages |

| Reflectivity | High (up to 1200 CPL for white/yellow) | Higher reflectivity means higher price |

| Washability | Can be washed with proper sealing strips | Requires sewing care to maintain performance |

| Color Options | Various colors, custom options available | Darker colors have lower reflectivity |

| Texture & Appearance | Smooth, shiny surface for professional look | Temporary creasing after folding |

| Warning Effect | Bright fluorescent colors attract attention | Color mixing risk if folded without isolation paper |

The Advantages and Disadvantages of PVC Reflective Tape

PVC reflective tape is a workhorse for visibility and safety—if used correctly. Its cold resistance, washability, and eye-catching colors make it ideal for harsh environments or high-traffic areas—just factor in the cost vs. reflectivity trade-off and prep customers on proper sewing/storage.

Whether you are equipping safety personnel, upgrading workwear, or designing high-visibility gear, our PVC reflective tapes make it easy to bring a bright effect. Contact us today to learn more.

Related blogs