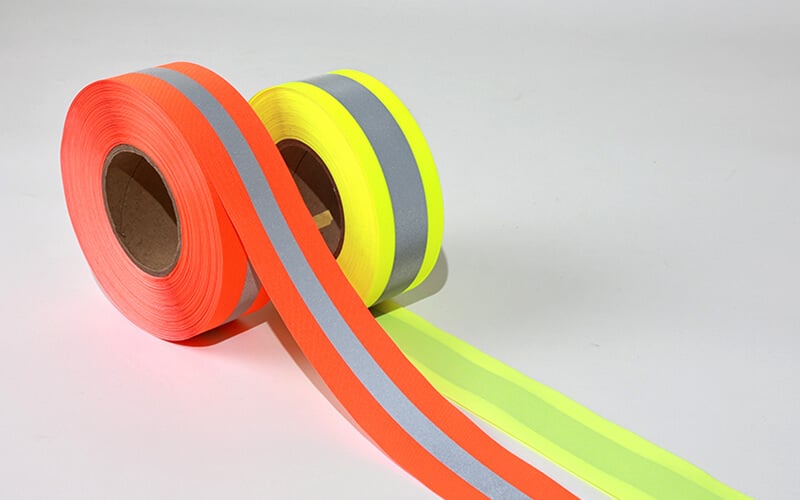

Reflective ribbon tape process: iron on and sew on

MAX Reflective Accessories Design Director

Reflective ribbon tape is a game-changer for safety, visibility, and even fashion. Whether you’re designing high-visibility workwear, outdoor gear, or adding flair to a DIY project, understanding the materials and processes behind reflective tape is key.

Let’s break down how these tapes are made and the two primary application methods: iron-on and sew-on.

What makes up a reflective ribbon tape?

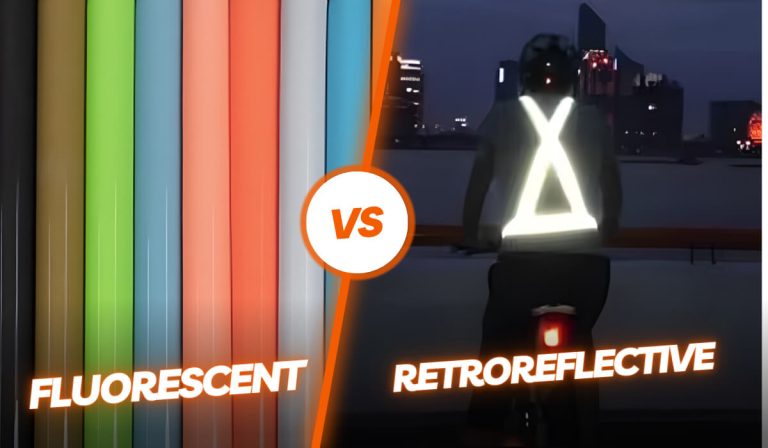

Reflective ribbon tape is more than just a shiny strip. It’s a combination of materials designed to be durable, flexible, and highly visible. The tape generally consists of two main parts:

1. The reflective middle layer

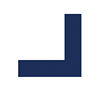

This is the heart of the tape—the part that reflects light. There are a few types:

- Reflective narrow strips: These are available in various properties and substrates. For example, you might find 100% polyester high reflective tape, silver reflective T/C reflective tape, or industrial washing reflective cloth. Each type has its strengths, such as durability or brightness.

- Reflective heat transfer film: This is a thin film that can be applied with heat. It often comes with patterns, which is excellent if you want to add logos or designs while keeping the reflective function.

2. The base material

The reflective layer needs a sturdy base to hold it in place and provide structure. Common base materials include:

- 100% Polyester woven tape: This is a popular choice due to its strength, availability in various weights, sizes, and colors, as well as its suitability for a wide range of applications.

- Narrow 300D Oxford cloth: Typically found in bright, fluorescent colors such as yellow, orange, or navy blue, this fabric is durable and highly visible, even without reflectivity.

- Elastic band: Used when stretch is needed, such as in sportswear or adjustable gear.

100% Polyester Knitted Fabric: Offers flexibility and comfort, often used in clothing where movement is essential.

Reflective ribbon tape process: sew-on vs. iron-on

The manufacturing process involves combining the reflective middle layer with the base material. The reflective strip is typically placed in the middle, sandwiched between layers or bonded on top, depending on the method. There are two main ways to attach reflective tape to fabric:

Sew-on reflective tape

What is sew-on?

Sew-on reflective tape is exactly what it sounds like—the tape is stitched onto the fabric.

This method is traditional and widely used, particularly for workwear and gear that requires withstanding harsh conditions.

How it works?

The reflective tape is cut to size and sewn onto the garment or item using industrial sewing machines. The stitching not only holds the tape in place but also reinforces the bond, making it very durable.

Pros of sew-on tape

- Durability: The stitching makes the tape last through heavy use and multiple washes.

- Versatility: Works well on thick or textured fabrics, such as denim, canvas, or leather.

- Strong bond: Less likely to peel or come off compared to adhesives.

Cons of sew-on tape

- Visible stitching: The stitches are visible, which may not be ideal for all designs.

- Labor-intensive: Sewing takes more time and effort, which can increase production costs.

- Less flexible: The tape and stitching can reduce fabric stretch or flexibility.

Best uses for sew-on tape

- Work uniforms and safety gear

- Outdoor equipment like backpacks and tents

- Heavy-duty clothing that needs to last

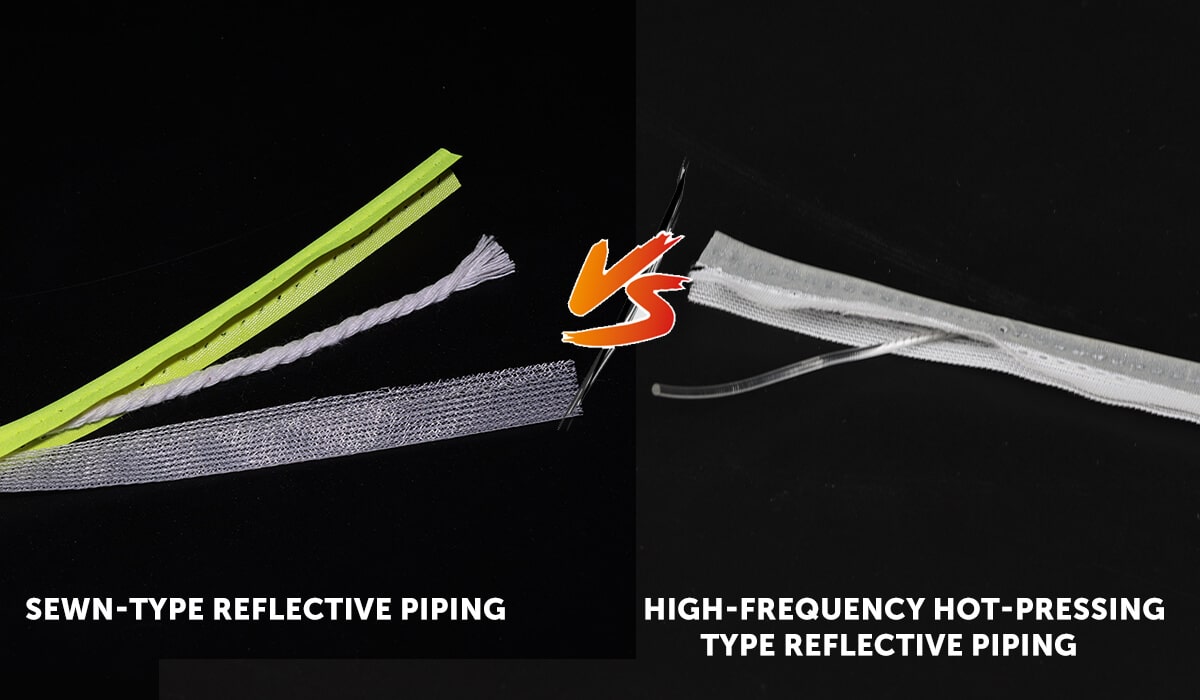

Reflective Ribbon Tape vs. Other Reflective Materials

Iron-on reflective tape

What is iron-on?

Iron-on reflective tape utilizes a heat-activated adhesive to bond the tape to the fabric. This method is popular for quick application and for items where sewing isn’t practical.

How does it work?

The tape has a heat-sensitive glue on the back. Using a heat press or even a household iron, the tape is pressed onto the fabric. The heat melts the adhesive, securely bonding the tape.

Pros of iron-on tape

- Clean look: No visible stitching, so the tape looks smooth and seamless.

- Quick application: Faster than sewing, which is great for small batches or DIY projects.

- Suitable for delicate fabrics: Works well on lightweight or thin materials that traditional sewing methods may damage.

Cons of iron-on tape

- Less durable: The adhesive can weaken over time, particularly with frequent washing or exposure to high temperatures.

- Not ideal for stretchy fabrics: The tape may peel off if the fabric stretches a lot.

- Heat sensitivity: Some fabrics can be damaged by the heat needed to apply the tape.

Best uses for iron-on tape

- Sportswear and activewear

- Casual clothing and reflective accessories

- Quick repairs or custom designs

Choosing between sew-on and iron-on

When deciding which method to use, consider these factors:

Factor | Sew-On Tape | Iron-On Tape |

Durability | High, withstands heavy use | Moderate, may peel with washing |

Fabric Type | Thick, textured, or heavy fabrics | Lightweight, delicate fabrics |

Appearance | Visible stitching | Smooth, no stitching visible |

Application Speed | Slower, more labor-intensive | Faster, easier for small runs |

Flexibility | Less flexible due to stitching | More flexible, but can peel |

Cost | Higher due to labor | Lower for small quantities |

Final thoughts

Whether you opt for sew-on ruggedness or iron-on convenience, reflective ribbon tape strikes a balance between durability, aesthetics, and practicality. By matching the right materials and methods to your project, you’ll create products that shine—literally—in any scenario.

Related blogs