The difference between Hi-Vis and reflective materials

MAX Reflective Accessories Design Director

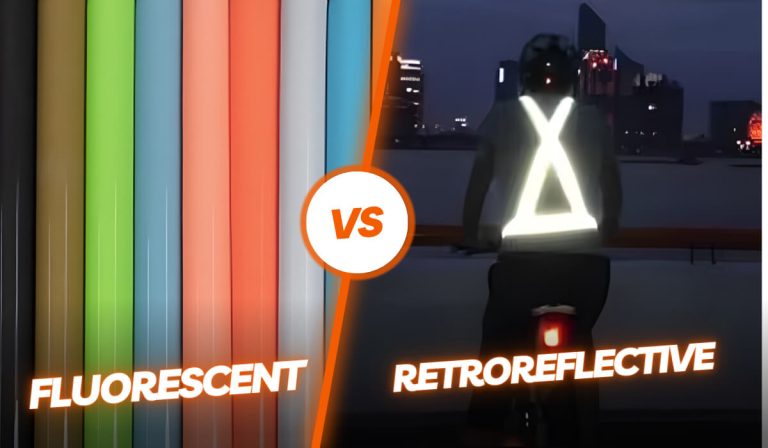

The terms “Hi-Vis” (high visibility) and “reflective materials” are often used interchangeably in safety apparel and workwear. While both are essential for increasing visibility, especially in low-light or high-risk environments, they are fundamentally different.

High-visibility clothing uses bright colors like yellow or orange to make the wearer stand out, especially in daylight or low-light conditions. These materials are ideal for situations such as construction zones, busy streets, or daytime cycling where being seen quickly can prevent accidents.

Reflective materials, on the other hand, are designed to bounce light back to its source. They shine when hit by headlights or streetlights, making them most effective at night or in very dark conditions.

In short, hi-vis materials are best suited for daytime visibility, while reflective materials enhance nighttime safety. Understanding the differences between them helps you choose the right protective gear for different work or activity scenarios.

This article will help you more to understand the differences between these materials and how they help keep you safe.

What is Hi-vis material?

High-visibility (hi-vis) materials are specially designed fabrics that make the wearer stand out in various environments, particularly in daylight or low-light conditions. These materials are made using fluorescent fibers or coatings that enhance visibility by absorbing and emitting UV light, making the colors appear extremely bright and vivid.

Common hi-vis colors include neon yellow, orange, green, and pink—chosen for their ability to contrast sharply against most backgrounds. This visual distinction helps ensure that individuals wearing hi-vis gear are easily seen from a distance.

Hi-vis materials are widely used in settings where safety is a priority, such as construction sites, roadwork, agriculture, forestry, and other outdoor jobs. By improving daytime visibility, hi-vis clothing helps reduce the risk of accidents and keeps workers safe.

What is reflective material?

Reflective materials are designed to enhance visibility in dark or low-light environments by bouncing light back toward its source, such as headlights or street lamps. They are typically made using glass beads or microprisms that reflect incoming light, making the wearer appear bright and noticeable at night.

Unlike hi-vis materials, which rely on bright colors for daytime visibility, reflective materials only become visible when illuminated by an external light source. This makes them especially useful for nighttime safety.

Reflective materials are commonly used in road safety gear, emergency service uniforms, nightwear, and any situation where visibility in the dark is essential to prevent accidents.

Key differences between hi-vis and reflective materials

Hi-Vis and reflective materials both improve visibility and safety, but they work in different ways and are suitable for different conditions. Here’s a detailed comparison:

Functionality

- Hi-Vis Materials:

Designed to enhance visibility in daylight or well-lit environments. They do not require an external light source to be effective.

Common in construction, roadwork, and outdoor daytime activities. - Reflective Materials:

Work by reflecting light back to its source, such as headlights. They are only effective in low-light or nighttime conditions.

Common in nightwear, emergency services, and nighttime roadwork.

Visibility in Lighting Conditions

- Hi-Vis Materials:

Bright fluorescent colors stand out in natural daylight or under artificial light. Visibility is not dependent on external light sources. - Reflective Materials:

Best used in low-light or dark conditions. They become highly visible only when illuminated by external light (e.g., headlights or flashlights).

Material Composition

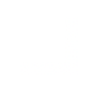

- Hi-Vis Materials:

Made from brightly colored, fluorescent fabrics (neon yellow, orange, green, pink). These materials absorb UV light and emit visible light to appear brighter. - Reflective Materials:

Made using glass beads, microprisms, or retroreflective tape. These materials reflect incoming light back toward its source.

Design Application

- Hi-Vis Materials:

Often used for full garments (vests, jackets, shirts) made entirely from bright fabrics. - Reflective Materials:

Typically applied as strips or patches on garments—around the arms, legs, or torso—to enhance nighttime visibility. Often combined with hi-vis clothing for 24-hour protection.

Durability and Maintenance

- Hi-Vis Materials:

More prone to fading and wear from frequent washing or sunlight exposure. Requires regular replacement and careful maintenance. - Reflective Materials:

More durable but require proper care to maintain reflectivity. Should be kept clean and free from damage to preserve performance.

Cost Considerations

- Hi-Vis Materials:

Generally more affordable and easier to produce. However, they may need to be replaced more often due to fading or fabric wear. - Reflective Materials:

Typically more expensive due to complex manufacturing. Offer better long-term value with proper maintenance.

Best Use Cases

- Hi-Vis Materials:

Ideal for daytime work in construction zones, roadworks, warehouses, and outdoor settings. - Reflective Materials:

Best for nighttime work, emergency services, or any situation where visibility depends on light sources like headlights or flashlights.

Reflective Ribbon Tape vs. Other Reflective Materials

How hi-vis and reflective materials work

Understanding how high-visibility and reflective materials function helps explain why both are essential for safety in different environments and times of day.

How do hi-vis materials work?

Hi-vis (high-visibility) materials use bright fluorescent colors like neon yellow, orange, and green to stand out in natural daylight or well-lit environments. These materials:

Are made with fluorescent pigments that absorb ultraviolet (UV) light and re-emit it as visible light.

Appear brighter than regular colors, making the wearer more noticeable in daylight, fog, or overcast conditions.

Do not rely on external light sources to be effective.

This high visibility reduces the risk of accidents in busy or hazardous environments, especially during the daytime.

How do reflective materials work?

Reflective materials are designed to increase visibility in low-light or dark conditions. They contain tiny glass beads or microprisms that reflect light back toward its source (like headlights or flashlights). These materials:

Use retroreflection to make the wearer visible from a distance in the dark.

Are only visible when illuminated by a direct light source.

Are often applied as strips or patches on clothing, gear, or equipment.

This feature is essential for nighttime safety, especially for workers near moving vehicles or machinery.

How do they work together for 24-hour visibility?

When hi-vis and reflective materials are combined on the same garment, they offer full-day protection:

Daytime: High-visibility colors stand out in daylight and low-light conditions, such as fog or twilight.

Nighttime: Reflective strips illuminate brightly, ensuring visibility in the dark.

This combination is vital to meeting safety standards such as ANSI/ISEA in the U.S. and EN ISO in Europe, which require garments to provide visibility under various lighting conditions.

Choosing the right gear for different conditions

Selecting appropriate high-visibility, reflective safety gear is essential to ensure workers remain visible and protected in any environment. The right material depends on several factors, including the work setting, lighting conditions, and industry regulations. At MAXReflect, we help you make informed choices to meet both safety standards and on-the-job demands.

1. Environmental conditions

The first step is to evaluate the environment where the gear will be used:

- Daylight or Well-Lit Areas: High-visibility materials, such as fluorescent yellow, orange, or green, are effective in daylight and well-lit conditions. These colors stand out by absorbing and emitting light, making the wearer highly visible.

- Low-Light or Night Conditions: Reflective materials are essential when visibility depends on artificial light, such as vehicle headlights. These materials bounce light back to its source, ensuring the wearer is seen even in the dark.

- Mixed Lighting (Day and Night): In environments where visibility is needed 24/7—such as roadwork, construction, or emergency response—a combination of hi-vis and reflective materials is recommended.

2. Time of Use

- Daytime Work: Fluorescent hi-vis materials are ideal.

- Nighttime Work: Reflective materials are necessary.

- 24-Hour Work: Choose garments that combine both for continuous visibility.

3. Application Requirements

Consider the specific tasks or industry needs:

- Construction: Workers often face both daylight and night conditions. Combining hi-vis and reflective materials is essential for round-the-clock safety.

- Emergency Services & Roadwork: Reflective gear is crucial for night visibility, while hi-vis works well during the day.

- Outdoor Activities or Events: Use materials suited to the environment and visibility needs, especially for sports, crowd management, or maintenance crews.

Conclusion

Hi-Vis and reflective materials each serve a vital role in ensuring safety and visibility. Hi-Vis fabrics offer high visibility during daylight hours with their bright fluorescent colors, while reflective materials shine in low-light or nighttime settings by reflecting light back toward its source. When combined, these materials provide comprehensive, 24-hour visibility, making them essential in industries such as construction, roadwork, and emergency services.

Understanding the differences between these materials helps in selecting the right gear for various work environments and ensures your team stays protected no matter the time of day.

As part of a professional hi-vis and reflective accessories manufacturer in China, MAXReflect is dedicated to producing high-quality, certified materials that meet the toughest safety standards. With rising demand for visibility gear, we continue to innovate—focusing on durability, brightness, and sustainable options that help reduce accidents and save lives.

Don’t wait until visibility becomes a safety issue. Choose the right gear now. Contact MAXReflect to explore our full range of hi-vis, reflective, and combination safety materials—designed to keep workers visible, safe, and compliant in every condition.

Related blogs

Related products

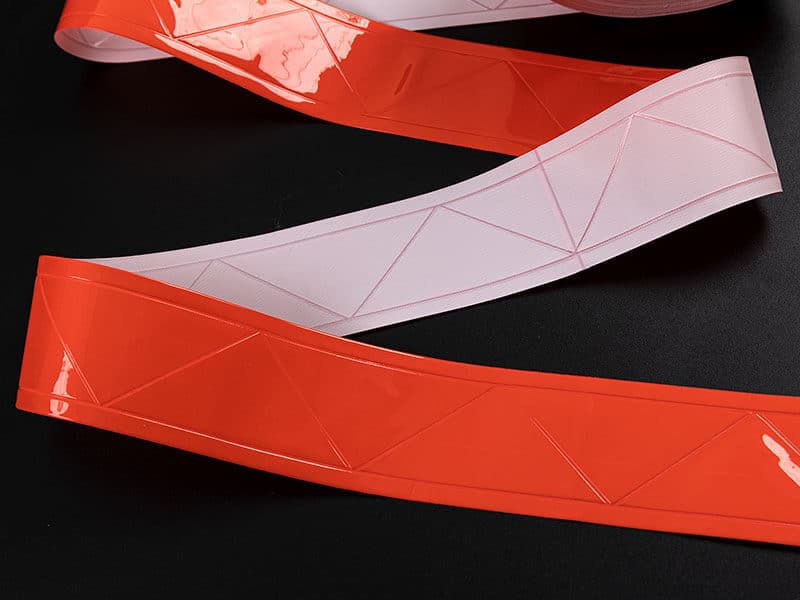

Reflective Heat Transfer Vinyl