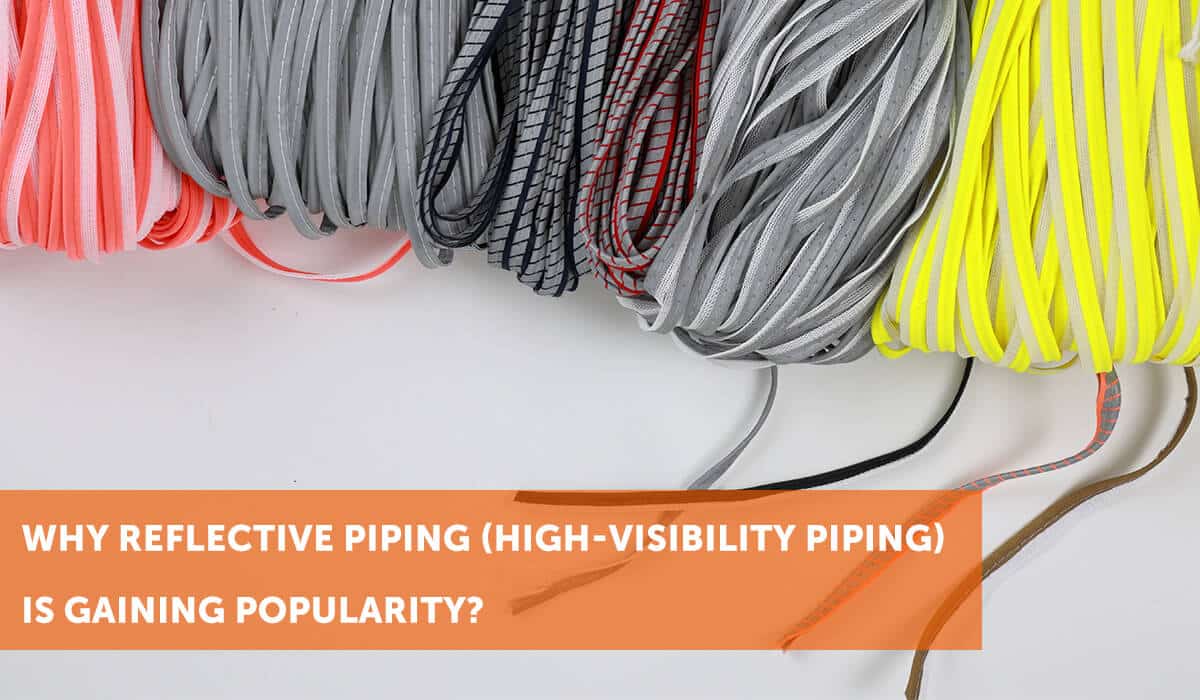

Healing the "Hidden Wounds": Scaling Quality in Reflective Piping Production

The "Hidden Wounds" on the Production Line: A Deep Dive into Reflective Piping

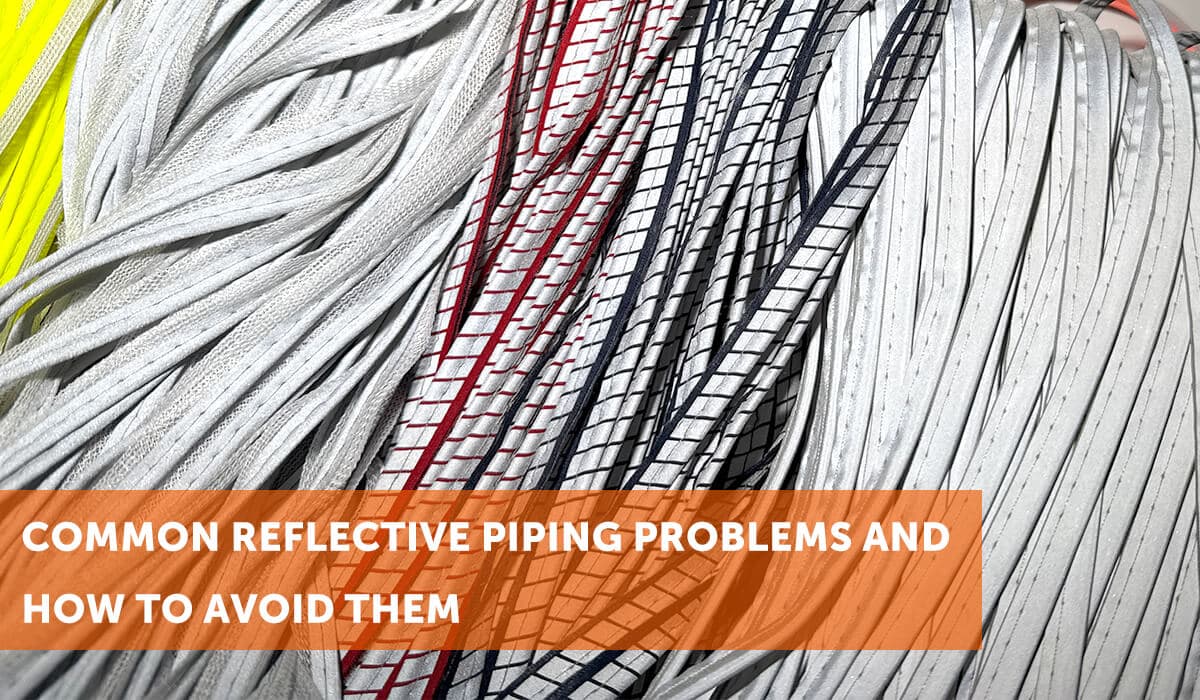

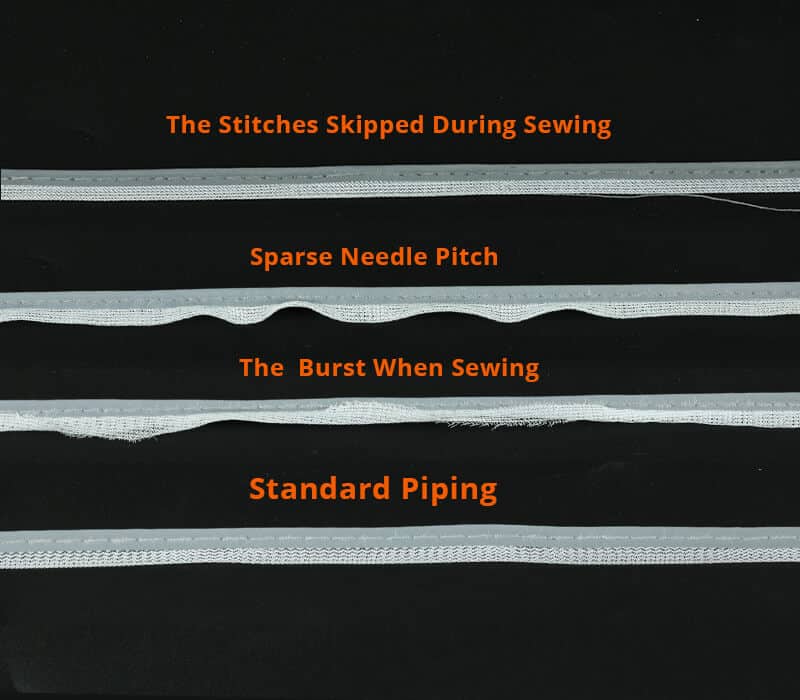

It’s 2:00 AM, and the workshop lights are still blazing. This isn’t a push to finish a reflective material urgent order. Instead, a team comprising the workshop director, quality control (QC), and technical staff huddles together, their expressions grim. During a mid-process inspection for a batch of reflective piping about to be shipped, they discovered inconsistent reflectivity, peeling, and skipped stitches. This is the second time this month.

In manufacturing, “small components” like reflective piping are often the most persistent “big headaches.” Though they may seem insignificant, they directly impact product safety, aesthetic quality, and—most importantly—customer trust. Today, we’ll discuss this “love-hate” relationship we have with reflective piping.

Lessons Learned — Typical Issues in Production

1. The "Roll of the Dice" Yield Rate

The Phenomenon: Using the same raw materials and the same equipment, the pass rate might be 95% today but drop to 90% tomorrow. Without a clear cause, the blame is often shifted to “tight deadlines” or “worker fatigue”.

The Root Cause: Unstable process parameters and a lack of Standard Operating Procedures (SOP). Minor fluctuations in thread tension, traction speed, or sewing equipment precision can have a massive impact.

2. The "Invisible Cost Killer."

The Phenomenon: To pursue “cost-effectiveness,” we previously purchased reflective fabrics in various widths (e.g., 50cm, 10cm, or 140cm). However, during production, we found that there was a lot of waste after Oblique cutting at 1.3cm, 1.5cm, or 2cm, resulting in high scrap rates.

The Root Cause: Focusing only on explicit procurement costs while ignoring “total cost of ownership,” which includes waste, efficiency, and quality risks.

3. The "Silent" Supply Chain

The Phenomenon: Suppliers deliver late, or the product arrives only for us to find it fails performance standards—such as insufficient reflectivity or poor surface appearance. This disrupts production schedules and leaves us reactive.

The Root Cause: A lack of supply chain synergy and reliable data verification. There was no consensus or pre-delivery testing on key indicators such as reflective power or wash/friction cycles.

Analyzing Core Pain Points

Pain Point 1: Brand Reputation

A single failure in reflective piping can cause high-end outdoor gear to lose its safety functionality at a critical moment, leading to customer churn and brand damage.

Pain Point 2: Eroded Profit Margins.

Frequent downtime for debugging and rework consumes valuable labor, time, and production capacity.

Pain Point 3: High Internal Friction

Production, QC, procurement, and sales departments often end up in “tug-of-war” disputes over piping issues, draining internal energy.

Pain Point 4: Disputes with customers

If the goods are shipped and the customer finds problems upon receipt, it will lead both parties into a long-term battle to constantly solve the problems, resulting in excessive consumption.

Our "Breakthrough" Strategy — Insights and solution

1. Establishing "Digitalized Process Cards"

- Action: We created detailed process parameter archives for every reflective piping product. Instead of broad ranges, parameters are tailored to specific base fabrics (100%polyester, T/C, or 100% cotton) and the abrasion resistance of the reflective coating.

- Example: For a synthetic reflective fabric with a 1.3cm bias-cut width, we specify a size 21 needle, flat-bed sewing, two stitches per cm, and a speed set to 605 meters per hour.

- Result: Raw data and tables were transformed into replicable, trainable “knowledge assets.” Even new employees can start quickly, and yield fluctuations are now controlled within 2%.

2. "Deep Integration" with Suppliers

- Action: We moved beyond simple transactions by inviting core suppliers’ technical staff to our factory to form a “Joint Process Improvement Group”. We ensure they understand that quality precedes quantity. We confirm specifications (e.g., 0.2cm cotton core) before ordering, based on pre-production samples, and conduct secondary quality checks on bulk samples.

- Result: The relationship shifted from “You supply, I use” to “Joint R&D.” Compatibility between materials and downstream processing has dramatically improved, yielding a “1+1 > 2” effect.

3. Introducing "Pre-emptive QC" and Rapid Testing Tools

- Action: Before reflective strips, cotton cores, or mesh fabrics enter the warehouse, we added a simple but critical “combination quality inspection”. Unqualified batches are rejected immediately, preventing issues from reaching the production line.

- Result: Unexpected production downtime decreased by 23%, and the schedule attainment rate improved significantly.

Get in Touch

Response within 24 hours.

Customised Safety Accessories for Every Need-MAX

The "discipline" of manufacturing is found in the daily process of solving specific problems. Reflective piping is just a microcosm of the countless challenges we face on the shop floor. We are grateful for our customers' support and their patience during delays. This journey has taught us that real cost reduction and efficiency gains come from deep mastery of every detail and a commitment to continuous improvement—a commitment shared by everyone here at MAX.

- [email protected]

- +86 19706839773