Iron-On Reflective Tape for Clothing

Iron-on reflective tape offers a simple, cost-effective, and highly durable solution. By transforming ordinary garments into high-visibility apparel, it provides peace of mind without the need for bulky safety vests.

Whether you are hitting the pavement for an evening run, cycling through dim streets, working on a construction site, or simply walking home after sunset, being seen can mean the difference between safety and danger. Most everyday clothing is not designed to reflect light, leaving pedestrians and workers vulnerable in low-light conditions. As a professional reflective tape manufacturer, MAX is committed to providing comprehensive solutions that combine safety, durability, and style.

What is iron-on reflective tape?

Iron-on reflective tape is a reflective material designed to enhance visibility. It consists of two main layers: a high-performance reflective layer and a heat-activated adhesive layer. When heat is applied using a standard iron or heat press, the adhesive melts and bonds securely to fabric fibers, creating a durable attachment that withstands washing and daily wear.

The Science: retroreflection

The core technology behind these tapes is retroreflection. Unlike standard glossy surfaces that scatter light, reflective tape bounces light directly back to its source (such as a car’s headlights). This creates a bright, glowing effect that alerts drivers to your presence long before they would see normal fabric.

There are two main technologies used:

- Glass-Bead Technology: The most common for clothing. It uses microscopic glass beads to reflect light. It is soft, flexible, and ideal for general activewear and casual clothing.

- Prismatic Technology: Uses micro-prisms for superior brightness. While often stiffer, it is excellent for industrial applications where maximum visibility is critical.

How to apply iron-on reflective tape

It is essential to apply iron-on reflective tape correctly to ensure durability and long-term performance. While the process may seem simple, proper preparation and technique can make the difference between tape that lasts for years and tape that peels off after a few washes.

Step 1: Prep the Garment

Ensure the fabric is clean, dry, and free of oils or fabric softeners, which can block adhesion. Pre-iron the area to remove moisture and wrinkles.

Step 2: Measure and Cut

Measure your desired length. You can cut the tape into strips, shapes, or designs.

Step 3: Position the Tape

Place the tape on the fabric with the reflective side facing up and the adhesive side down.

Step 4: Protect

Cover the tape with parchment paper or a thin cloth. Never apply the iron directly to the reflective surface.

Step 5: Apply Heat

Set your iron to the temperature recommended by the manufacturer (usually “Wool” or “Cotton” setting, approx. 140°C–160°C).

Step 6: Press Firmly

Press down with firm, even pressure for 10–20 seconds. Do not slide the iron around; lift and press if you need to cover a larger area. Do not use steam.

Step 7: Cool and Peel

Allow the tape to cool completely (unless instructions specify a “hot peel”). Gently peel off the clear plastic liner.

Step 8: Test the Bond

Gently tug at the edges. If they lift, cover and re-press for a few more seconds.

Why use iron-on reflective tape?

Integrating reflective tape into your clothing offers benefits that go beyond basic safety.

1. Enhanced Safety in Low Light

The primary benefit is visibility. Whether in fog, rain, or darkness, reflective tape ensures you are seen by drivers, cyclists, and equipment operators, significantly reducing the risk of accidents.

2. Comfort and Versatility

Unlike heavy vests or specialized gear, iron-on tape is lightweight and integrates seamlessly into your existing wardrobe. It moves with the fabric, maintaining the garment’s natural feel. It is versatile enough for:

- Activewear: Running shorts, leggings, and cycling jerseys.

- Workwear: Uniforms for construction, logistics, and night shifts.

- Daily Use: School backpacks, jackets, and pet accessories.

3. Cost-effective customization

Instead of purchasing expensive new safety gear, you can upgrade your favorite items at a fraction of the cost. It also allows for creative customization—add stripes, geometric patterns, or logos to make your gear both safe and stylish.

Choosing the right tape for your project

Not all reflective tapes are created equal. To ensure the best results, you must match the tape type to your specific fabric and activity.

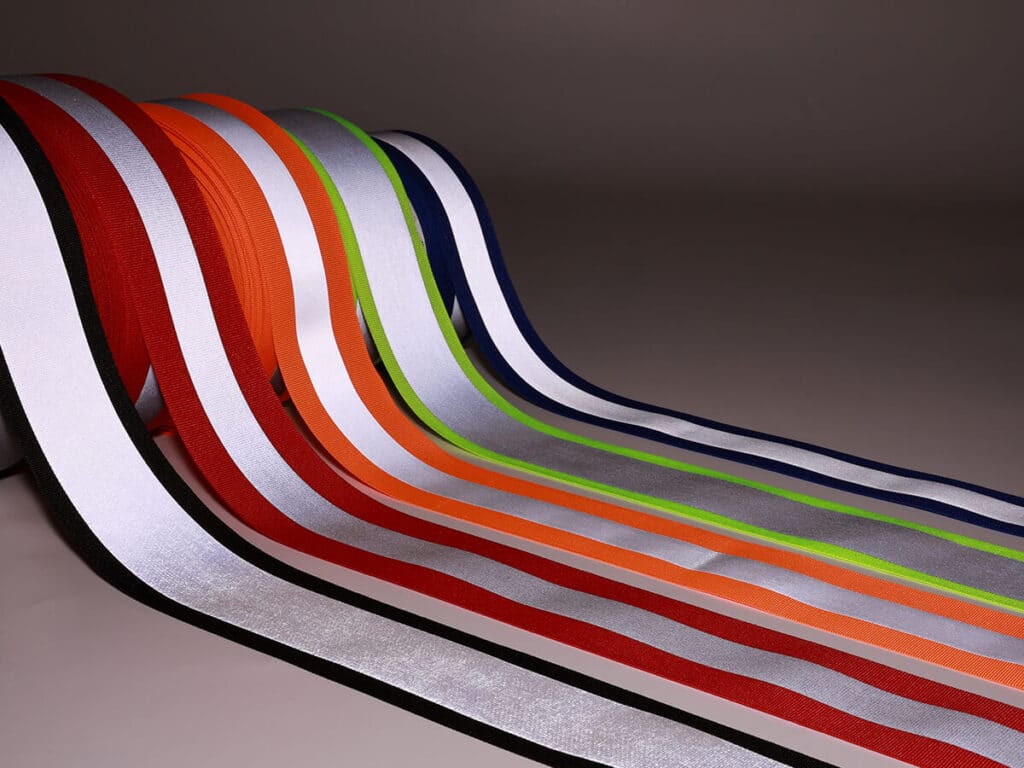

By material and function

- Standard polyester tape: Soft and flexible, perfect for cotton, polyester, and blends used in everyday clothing.

- Stretchable reflective tape: Designed for elastic fabrics like Spandex or Lycra. Essential for leggings and sportswear, as it moves with the body without cracking or peeling.

- Industrial & flame-retardant tape: Built for high-risk environments. These tapes resist heat and fire, making them essential for welders, firefighters, and industrial workers.

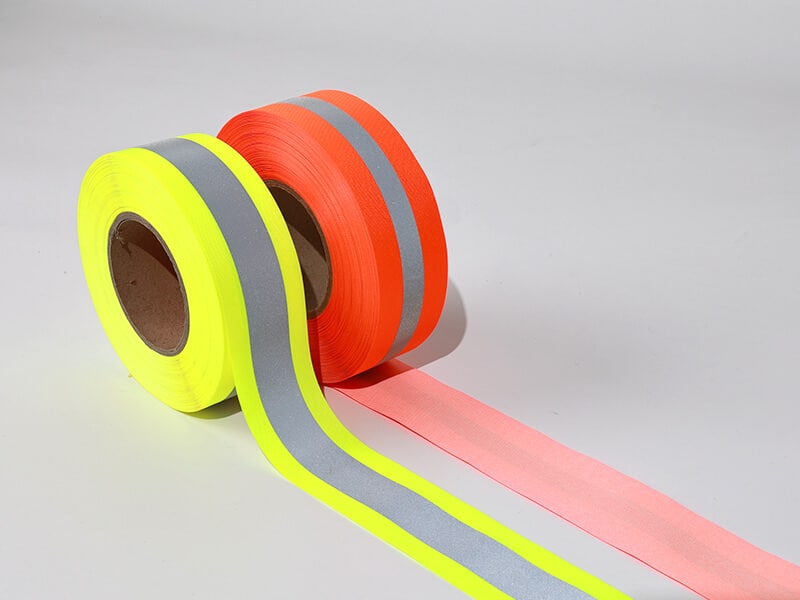

- Colored & fashion tape: While silver offers the highest reflectivity, neon colors (yellow, orange) and custom patterns enable high-visibility fashion designs.

Maintenance

Proper care ensures your reflective tape remains effective for years.

- Washing: Turn the garment inside out to protect the reflective surface. Use a gentle cycle with cold or warm water. Avoid harsh detergents and never use bleach.

- Drying: Air-drying is best. If you must use a dryer, select a low-heat setting. High heat can remelt the adhesive and cause shifting.

- Ironing: Never iron directly over the reflective tape. Iron around it or use a pressing cloth.

Get in Touch

Response within 24 hours.

Why Partner with MAX?

At MAX, we specialize in manufacturing high-quality, customizable reflective solutions that meet the diverse needs of our users. Don't rely solely on streetlights or driver awareness—take control of your visibility today.

Ready to enhance your safety or start your next creative project? Explore MAX’s range of iron-on reflective tapes and turn any garment into a smart safety solution.

- [email protected]

- +86 19706839773