Custom reflective logo

Customized reflective logos are both functional and stylish, enhancing safety equipment, sportswear, and fashion.

Custom reflective logo expert - MAX

At MAX, we specialize in custom reflective logos that combine bold design with enhanced visibility. Made from high-quality reflective materials, these logos improve visibility in low-light conditions while offering durability, versatility, and a stylish look. Whether you’re creating athletic apparel, protective gear, uniforms, or fashion pieces, our precision manufacturing and fully customizable options ensure your branding reflects your identity and purpose.

What are custom reflective logos?

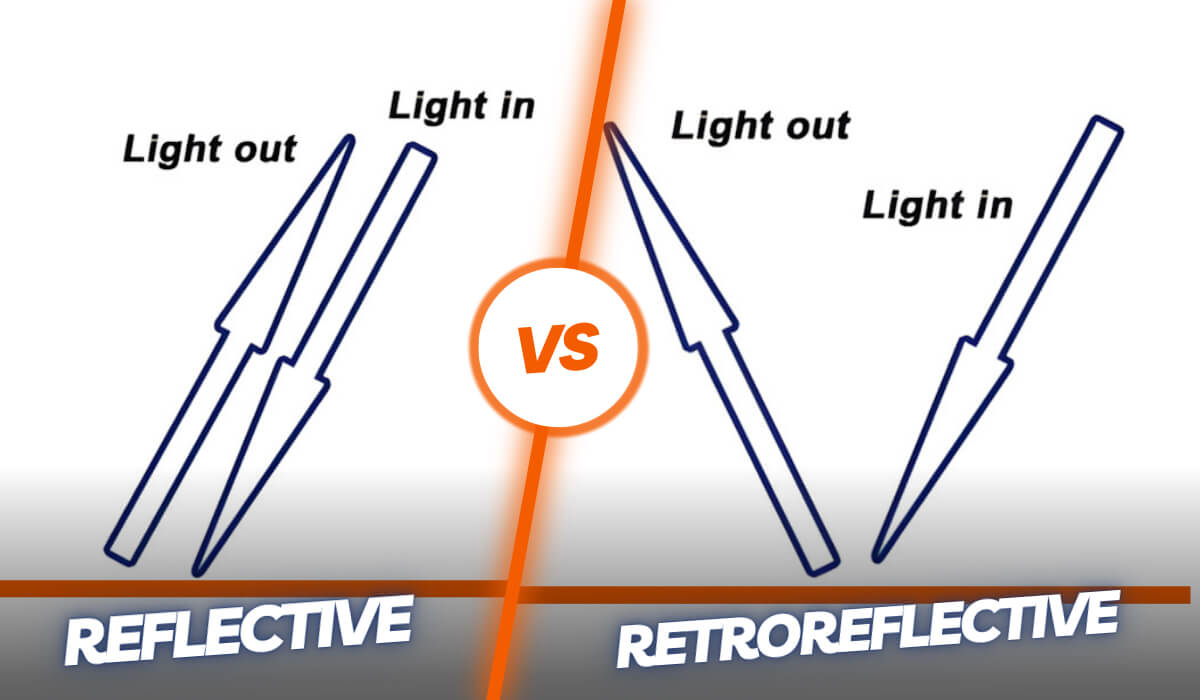

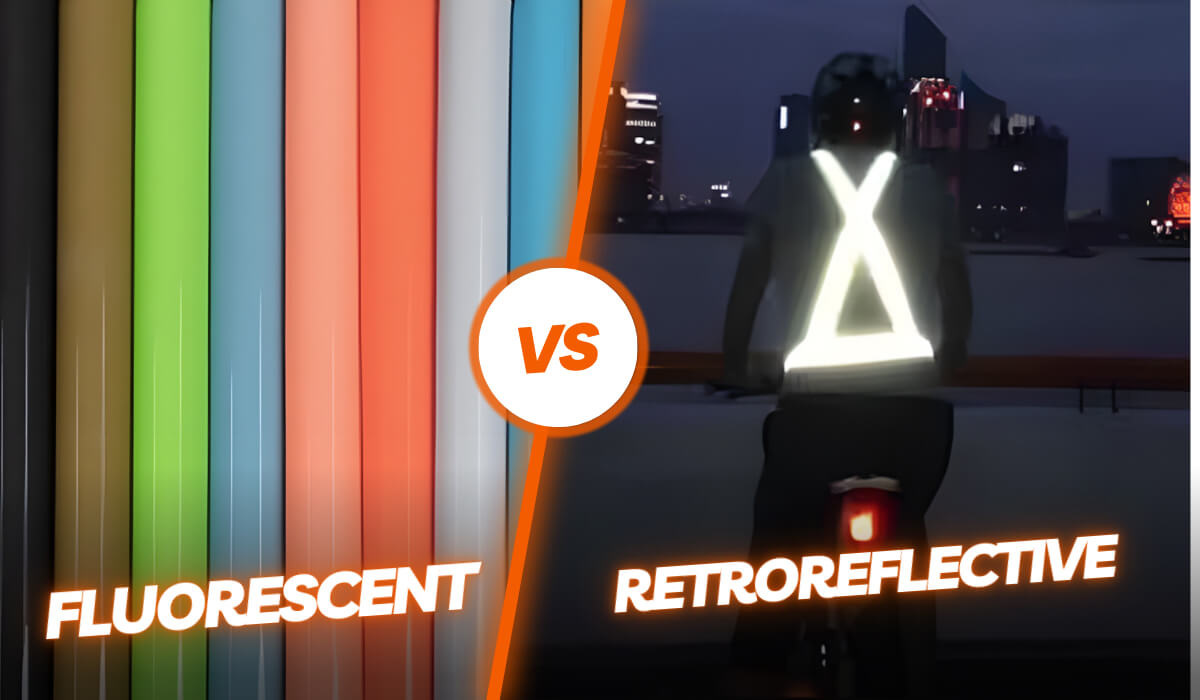

Custom reflective logos are specially designed brand marks or symbols that incorporate reflective materials to enhance visibility and safety. Unlike traditional logos printed with standard inks, reflective logos use materials such as glass beads, microprismatic films, or reflective threads that bounce light back to its source, making the logo highly visible in low-light or nighttime conditions.

Custom reflective logos are tailored to your brand’s needs, allowing for personalized designs, specific colors, and a strong brand identity that stands out both day and night.

Types of reflective materials for custom logos

Custom reflective logos can be made using various reflective materials, each offering different levels of reflectivity, durability, and application options.

Glass bead reflective material

This classic option uses tiny glass beads embedded in the surface to reflect light. It provides effective reflectivity from multiple angles and is widely used in safety vests, workwear, and uniforms.

- Pros: Good visibility, cost-effective, durable.

- Best For: Safety gear, general workwear, outdoor wear.

Microprismatic reflective material

Made with microscopic prisms, this material reflects light more efficiently and brightly than glass beads, especially over longer distances.

- Pros: Superior brightness and clarity, long-range visibility.

- Best For: High-visibility clothing, traffic signage, performance gear, premium fashion.

Reflective vinyl

A flexible and inexpensive material that can be cut into custom shapes and easily applied to various surfaces. It’s common on promotional items, signs, and even vehicles.

- Pros: Cost-effective, customizable, easy to apply.

- Best For: Promotional products, decals, bags, signs, and light-duty apparel.

Reflective fabric

Soft and flexible, reflective fabric is ideal for sewing or heat-applying onto clothing like jackets, pants, or uniforms. It’s often used where comfort and flexibility are also important.

- Pros: Comfortable, durable, washable.

- Best for: Workwear, sportswear, and fashion garments.

Retroreflective films

Thin, adhesive-backed films designed to reflect light back to its source, making them ideal for dark environments. They’re often used on vehicles, signs, and accessories.

- Pros: High reflectivity, professional appearance, and weather resistance.

- Best for: Vehicle decals, safety signs, branded accessories.

Quality control and testing

Reflectivity testing: Each batch of reflective logos undergoes photometric testing to measure the coefficient of retroreflection, ensuring compliance with safety standards such as ANSI/ISEA or EN ISO 20471.

Durability assessments: We conduct abrasion resistance, washability, and weather exposure tests to guarantee long-lasting performance.

Adhesion and flexibility checks: The logos are tested for adhesion strength and flexibility to ensure they withstand the intended use conditions without peeling or cracking.

After-sales support

Technical assistance: MAX provides ongoing support for installation guidance, maintenance tips, and troubleshooting.

Customization updates: We work closely with clients to refine designs or materials based on feedback and evolving market trends.

By maintaining strict control over each step of the manufacturing process, MAX ensures that every custom reflective logo not only meets but exceeds client expectations in terms of safety, quality, and visual impact.

The manufacturing process from a supplier’s perspective

Creating custom reflective logos involves a meticulous and technically advanced production process that ensures both high visibility and durability. As a specialized supplier of reflective materials, MAX Reflective follows a comprehensive workflow to deliver superior custom reflective logos tailored to client specifications.

Consultation and design collaboration

Design feasibility: Our design team will evaluate the logo artwork to determine the optimal reflective material and application method to ensure optimal reflectivity and aesthetics.

Material selection: Based on the design and intended use, we recommend appropriate reflective materials such as glass bead reflective film, microprismatic reflective sheeting, or reflective thread for embroidery.

Material preparation

Raw material inspection: We source high-quality reflective substrates that meet international safety and durability standards. Each batch undergoes rigorous quality checks for reflectivity, adhesion, and weather resistance.

Customization of reflective films: For logos requiring specific colors or finishes, we customize reflective films through processes like dyeing or lamination without compromising reflectivity.

Logo production techniques

Depending on the client’s requirements and the nature of the product, we employ various application methods:

Heat transfer printing

Reflective films are precisely cut into the logo shape using advanced CNC or laser cutting machines. The cut reflective logo is then heat-pressed onto the fabric or substrate, ensuring strong adhesion and flexibility.

This method is ideal for sportswear and safety apparel where durability and comfort are critical.

Embroidery with reflective threads

Reflective threads are used to stitch the logo directly onto garments or accessories.

This technique offers a premium textured finish and excellent durability, suitable for high-end fashion or corporate uniforms.

Screen printing with reflective inks

Reflective inks containing micro glass beads are screen-printed onto the surface.

This method allows for detailed designs and is often used for promotional items or casual wear.