Reflective ribbon tape

Reflective ribbon tape is safe and stylish, enabling the industry to protect workers and attract spectators. As a trusted manufacturer of reflective accessories, MAX offers tailored solutions to meet your exact needs.

Home » Reflective ribbon tape

Reflective ribbon tape manufacturer

With a commitment to excellence, Max Reflective company has established itself as a professional and reliable manufacturer of reflective accessories.

Reflective ribbon tape is a specialized adhesive material designed to enhance visibility in low-light conditions by reflecting light back to its source.

- Type: heat transfer or sewing reflective ribbon tape

- Compliance standard: ISO20471/ANSI107/CSAZ96/Oeko-tex

- Color: yellow, orange, red, or customized

- Width: customizable for both reflective ribbon tape and backing fabric.

- Backing material: Oxford, Ribbon, knitted fabric, woven fabric, or customized

- Reflective value: >300 cd/(lx.m2)

- Suitable for: Hi-vis safety garments, sportswear, bags, caps, and outdoor sports equipment, such as emergency rescue apparel.

High Visibility

Customizable

Safety Certified

Durable Material

Easy Application

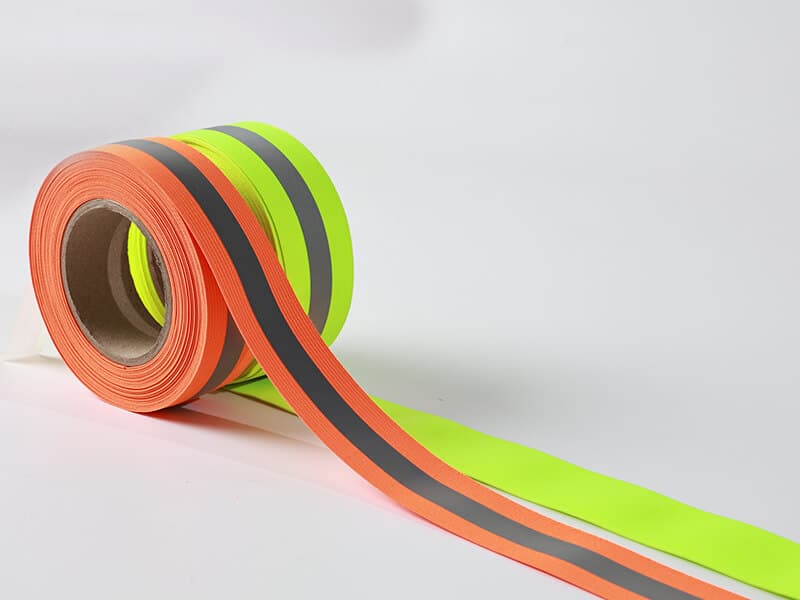

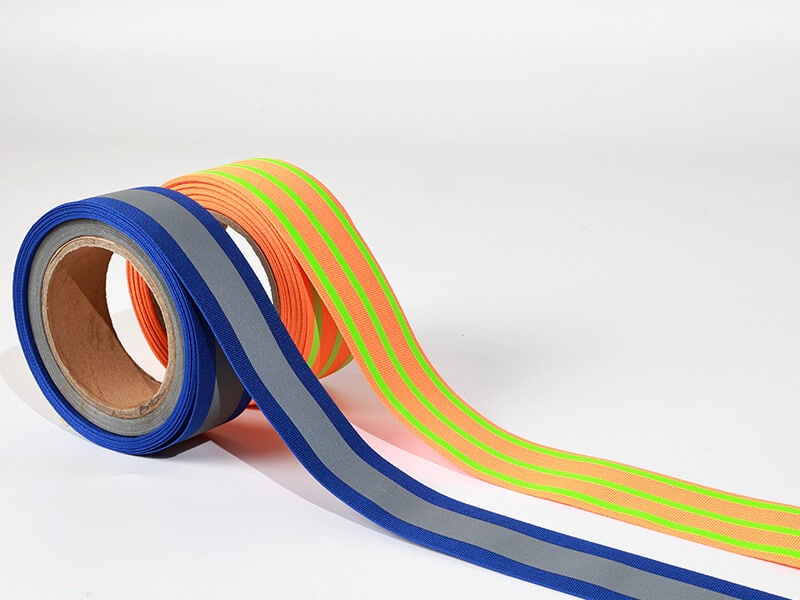

Heat transfer or sewing reflective ribbon tape

At present, the demand for reflective materials is not only satisfied with simple reflective strips, which has derived the combination of reflective strips with various materials and colors of fabrics, regardless of heat transfer or sewing methods, can perfectly achieve the coexistence of beauty and safety. This column is mainly about our webbing (ribbon )warning tape series. It also can be printed with any logo on the surface.

Iron-on reflective ribbon warning tape

- REF: MW0201

- Material: Unique hot composite materials with strong adhesive properties and high reflectivity. The basic woven tape is 100% polyester.

- Color: Fluorescent yellow, Fluorescent Orange, Red, black, Pink, etc.

- Size: 2.5cm, 5cm, 10cm, or customized size

- Wash: ISO 6330 home wash, Industrial wash, pre-shrunk.

- Reflective : >400 cd/(lx.m2)

Pattern silver reflective heat transfer webbing warning tape

- REF: MW0202

- Material: The 100% polyester ribbon & TPU or PES heat transfer vinyl.

- Compliance Standard: EN ISO20471/ ANSI107/ Oeko-tex 100

- Color: Fluorescent yellow, fluorescent orange, red, black, pink, etc.

- Figure pattern: customized laser making.

- Size: 5*2cm, 5*2.5cm, customized.

- Reflective: >350 cd/(lx.m2)

- Wash: ISO 6330 4N home wash

Reflective ribbon tape stitched

- REF: MW0203

- Material: The 100% polyester woven & 100% polyester /cotton reflective strips, as a DIY nature, exist to meet different standards.

- Color: Fluorescent yellow, fluorescent orange, Lime, Red, black, etc.

- Size: 5*2cm, 5*2.5cm, customized size.

- Reflective : >330 cd/(lx.m2)

- Wash: withstands multiple home washing, industrial washing

High-vis iron-on oxford reflective fabric tape

- REF: MW0204

- Material: The unique hot composite materials have strong adhesive properties and high reflectivity. The 100% polyester 300D oxford with PU coating. With water pressure 3000-5000mm.

- Color: Fluorescent yellow, fluorescent orange

- Size: 5*1.5cm, 5*2cm, 5*2.5cm, or customized.

- Reflective: >400 cd/(lx.m2)

Comprehensive guide to reflective ribbon tape

Reflective ribbon tape manufacturing process

Two primary technologies are used:

Glass Bead Technology

- Embedding glass beads: Microscopic glass beads (50–90 microns in diameter) are evenly embedded into the adhesive layer.

- Aluminization: Beads are coated with aluminum via vapor deposition to reflect light.

- Protective Sealing: A resin or PU layer locks the beads and enhances weather resistance.

Microprismatic Technology

- Embossing: A transparent PVC or polycarbonate film is heated and pressed with diamond-cut molds to create prismatic structures (cube corners).

- Metallization: Prisms are vacuum-coated with aluminum for reflectivity.

- Lamination: The prismatic layer is bonded to a polyester base for structural support.

Quality control and testing

- Reflectivity testing: Measured in candelas per lux per square meter (cd/lx/m²) under standardized angles using retroreflectometers.

- Peel adhesion test: Tapes are applied to substrates (steel, fabric) and peeled at 180° to assess bond strength.

- Abrasion resistance: Simulated wear tests (e.g., Taber abrasion) to ensure longevity in high-traffic areas.

- Compliance checks: Validation against ANSI/ISEA, EN ISO, or DOT standards.

Customization

Printing Technologies

- Screen Printing: UV-resistant inks are pressed through delicate mesh stencils to imprint logos and text.

- Hot Stamping: Metallic foils (gold, silver) or colored films are heat-transferred onto the tape using engraved dies.

Pattern and Shape Customization

- Die-Cut Symbols: Laser-cut arrows or company logos are integrated into the tape during slitting.

- Embossed Textures: Raised tactile surfaces for blind/visually impaired applications (ADA compliance).

Color Matching

- Colored Overlays: Translucent colored films (red for emergency services, green for forestry) laminated over reflective layers.

- Fluorescent Options: DayGlo® coatings combined with retroreflective beads for 24/7 visibility (ANSI 107-2020 Class 3).

Sizing and Edge Treatments

- Custom Widths: Ranging from ultra-narrow 5mm strips (helmet markings) to 100mm+ for truck trailer outlines.

- Edge Sealing: Heat-sealed polyester borders prevent fraying in high-abrasion environments (e.g., warehouse floor markers).

Customize your reflective ribbon warning tape

Elevate your safety and branding with our one-stop reflective ribbon tape service—tailored to your specifications, from precision prints to certified durability. Contact us today!

How to choose the right reflective ribbon tape

Selecting the appropriate reflective ribbon tape ensures safety compliance, durability, and cost efficiency. Below are key factors to consider, expanded with actionable insights:

Outdoor vs. Indoor Use

- Outdoor: Prioritize UV-resistant materials (e.g., PVC or polyester with UV stabilizers) to prevent fading. Look for tapes rated for temperatures between -30°C to 80°C to withstand extreme climates.

- Indoor: Opt for removable adhesives for temporary markings (e.g., floor signage in warehouses).

Chemical Exposure

In industrial settings (e.g., oil rigs, factories), choose chemical-resistant materials like PVC-coated tapes to maintain adhesion and reflectivity despite exposure to solvents or oils.

Moisture and Humidity

For marine or wet environments, select waterproof adhesives and sealed-edge designs to prevent peeling or water ingress.

- Fabric/Textiles: Use low-tack adhesives to avoid damaging clothing fibers. Ensure the tape is sewable (e.g., fabric-backed tapes for workwear).

- Metal/Plastic: High-tack acrylic adhesives ensure long-term bonding on vehicles, machinery, or traffic signs. Pre-treat surfaces with primers for extra adhesion.

- Painted Surfaces: Verify adhesive compatibility to avoid peeling paint. Test a small area before bulk application.

Reflectivity Performance

- Microprismatic Tape (Class 3): Ideal for high-risk environments (e.g., highway construction) with reflectivity values above 330 cd/lx/m².

- Glass Bead Tape (Class 1): Suitable for low-risk areas (e.g., indoor warehouses) with reflectivity values under 100 cd/lx/m².

Compliance

- ANSI/ISEA 107 (U.S.): Mandatory for safety apparel in roadwork.

- EN ISO 20471 (EU): Required for high-visibility clothing in European logistics or emergency services.

- DOT-C2 (Automotive): Ensures visibility for truck trailers and license plates.

Color: Fluorescent yellow/orange dominates safety gear, while silver/gray suits automotive or architectural use.

Width: Narrow tapes (10–20mm) work for helices on bike frames; wider rolls (50–100mm) mark shipping containers.

Printing: Screen-printed logos must retain reflectivity. Confirm print durability through abrasion testing.

Applications

Safety vest

Reflective belt