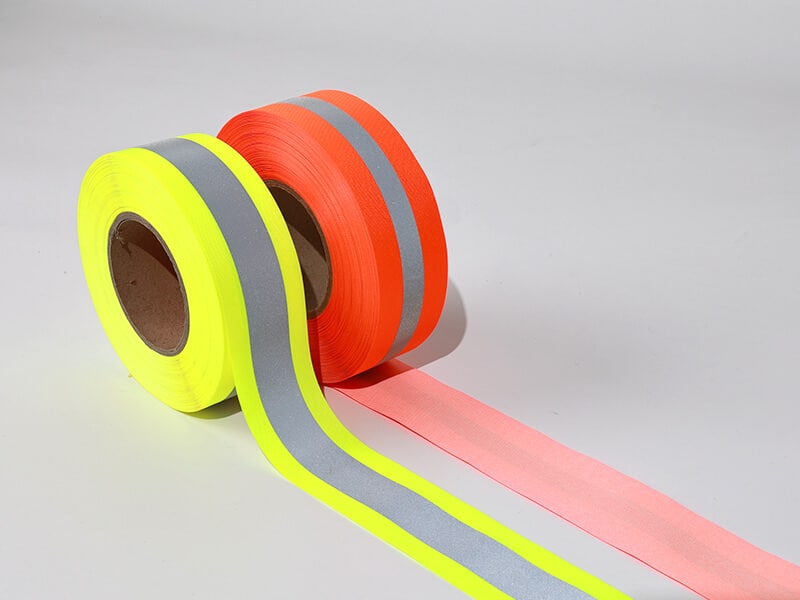

Fire resistant reflective tape

In the demanding landscape of industrial safety and emergency response, the margin for error is nonexistent. For professionals operating in high-heat environments—firefighters, foundry workers, and petrochemical engineers—visibility and thermal protection are not just features; they are lifelines.

At MAX, we specialize in the engineering and customization of high-tier reflective solutions. This article serves as a technical deep dive into Fire-Resistant (FR) Reflective Tape, exploring its material composition, international safety standards, and the strategic advantages of integration into professional personal protective equipment (PPE).

What is fire resistant reflective tape?

Fire-resistant reflective tape is a specialized safety material designed to stay visible and stay intact when exposed to extreme heat, sparks, and open flames. In simple terms, it is reflective tape built to survive high-temperature environments, helping workers stay seen and protected in dangerous, low-visibility conditions.

Unlike standard reflective tape, which can melt, burn, or lose reflectivity when exposed to high temperatures, fire-resistant reflective tape is engineered with heat-tolerant fabrics and flame-retardant coatings. This means it can handle environments where traditional tape would fail, ensuring visibility even around fire, molten metal, hot equipment, and intense radiant heat.

Because of its durability and safety performance, this type of tape is widely used in high-risk industries where both heat protection and visibility are critical.

By combining thermal resistance with high-visibility reflectivity, fire-resistant reflective tape provides reliable protection in environments where every second — and every layer of safety — matters.

Understanding the core utility

Standard reflective tapes are designed for high visibility under low-light conditions. However, in environments where open flames, radiant heat, or electric arcs are present, standard polyester-based tapes become a liability—they can melt, drip, or ignite.

Fire-Resistant Reflective Tape is engineered to provide two simultaneous layers of protection:

- Passive visibility: Utilizing retroreflective technology to return light to its source, ensuring the wearer is visible to vehicle operators and teammates.

- Thermal integrity: Utilizing flame-retardant substrates (typically 100% cotton or aramid fibers) that carbonize rather than melt when exposed to extreme heat.

Material Engineering and Construction

The performance of FR reflective tape is determined by its “sandwich” construction. Each layer must be meticulously bonded to ensure durability without compromising the flame-retardant properties of the base garment.

The Substrate (The Foundation)

The backing material is the most critical component for fire resistance. MAX typically utilizes two primary types:

- FR treated cotton: A cost-effective, breathable option treated with flame-retardant chemicals. It is ideal for industrial workwear where moderate heat protection is required.

- Aramid (Nomex®/Kevlar® equivalent): For high-stakes environments like structural firefighting. Aramid fibers are inherently flame-resistant, meaning their protection cannot be washed out or worn away.

The Reflective Layer (Micro-Glass Beads)

Most FR tapes utilize wide-angle retroreflective technology. Thousands of microscopic glass beads are coated with a reflective silver layer and embedded into a polymer resin. When light hits these beads, it is refracted and reflected back to the original light source (such as a truck’s headlights).

The Adhesive/Coating

In high-end FR tapes, the bonding agent between the beads and the fabric must also be flame-resistant. This prevents “delamination”—a common failure where the reflective silver layer peels off the fabric after heat exposure.

Technical performance metrics

When evaluating FR tape for customization projects, MAX focuses on three technical pillars:

A. Retroreflectivity ($R_A$)

Reflectivity is measured in candelas per lux per square meter ($cd/lx \cdot m^2$). High-quality silver FR tape typically exceeds $500 \ cd/lx \cdot m^2$, ensuring maximum visibility even in smoke-filled or rainy environments.

B. Heat Shrinkage and Char Length

Under the Vertical Flame Test, a high-performance tape should show minimal “char length” (the distance the fabric burns after the flame is removed). More importantly, the tape must not shrink excessively, as shrinkage can pucker the garment and restrict the wearer’s movement during an emergency.

C. Industrial Wash Durability

Professional PPE is subjected to harsh cleaning cycles to remove soot, oils, and toxins. Our FR tapes are tested to maintain their reflective properties for up to 50–100 cycles of industrial laundering at temperatures of 60°C or higher.

Common Challenges and MAX Solutions

The "Brittle" Problem

Some FR coatings make the tape stiff and crack over time. MAX uses flexible polymer binders to keep the tape soft and flexible, so it moves with the wearer.

Edge Fraying

In heavy-duty industrial use, the edges of the tape can catch and tear. We recommend specific stitching patterns and reinforced backing to mitigate this.

Chemical Resistance

In the petrochemical sector, tapes are often exposed to fuels and solvents. Our premium FR tapes feature a protective top-coat that resists chemical dulling.

Customization and strategic application

At MAX, we understand that “one size fits all” does not apply to safety. Customization is where intelligence meets design.

- Triple-trim configurations: A popular choice for firefighters, featuring a fluorescent lime-yellow or orange border with a silver reflective center. This provides “Enhanced Visibility”—the fluorescent colors provide daytime conspicuity, while the silver center provides nighttime reflectivity.

- Perforated designs: For high-exertion roles, we offer perforated FR tape. Small laser-cut holes allow for better breathability and moisture vapor transition, reducing the risk of heat stroke for the worker.

- Logo integration: Using specialized heat-transfer or silk-screening methods, we can incorporate company branding directly onto the FR reflective surface without compromising the safety rating.

Get in Touch

Response within 24 hours.

Why Partner with MAX?

Fire-resistant reflective tape is a small component of a safety garment, but its role is monumental. It represents the intersection of optical physics and textile engineering. By choosing high-performance materials and adhering to global standards, organizations ensure that their most valuable assets—their people—are seen and protected.

As a specialized factory, MAX bridges the gap between raw material science and finished product utility. We don't just supply tape; we provide comprehensive safety solutions.

- [email protected]

- +86 19706839773