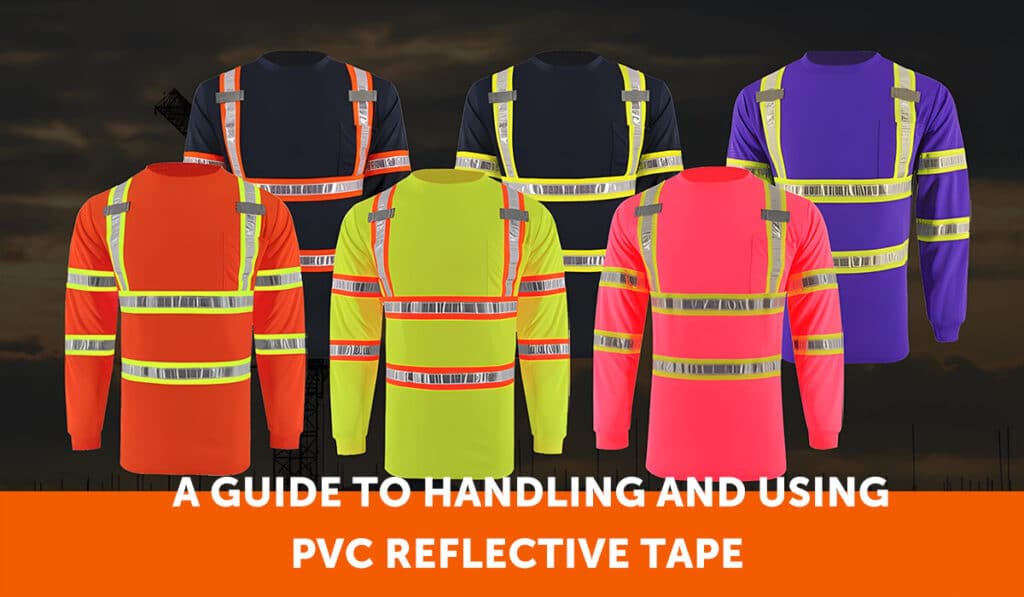

A Guide to Handling and Using PVC Reflective Tape

MAX Reflective Accessories Design Director

PVC reflective tape is widely used in safety gear, signage, and other applications due to its durability and reflective qualities. However, improper handling and application can lead to performance issues. Below, we discuss common problems manufacturers or users face with PVC reflective tape and provide practical solutions to avoid them.

Recovery issues after folding

When PVC reflective tape is sewn onto a reflective vest or clothing, it may take time to recover its original flat shape after being folded. This can temporarily affect the overall visual appearance and reflective performance.

How to avoid it

- Select higher-quality PVC reflective tape that is designed for flexibility and quick recovery.

- Properly store finished garments to minimize folding or creasing. Using hangers, instead of folding, can help.

- If folding is unavoidable, gently press the material before use to help it regain its shape.

Color bleeding when using colored PVC reflective tape

Using colored PVC reflective tape, especially in wet, humid, or hot environments, may cause color bleeding. This can stain the surrounding fabric and diminish the overall product quality.

How to avoid it

Place a thin layer of isolation paper between folded sections of the colored tape during storage or transportation. This will prevent direct contact that could lead to bleeding.

Always perform a colorfastness test before sewing the reflective tape onto garments, especially if the product will be exposed to high temperatures or moisture.

Edge breakage due to poor stitch control

Improper sewing techniques can cause edge breakage, resulting in a shorter lifespan of the reflective tape. This problem typically occurs due to excessive stitching density or poorly aligned sewing.

How to avoid it

- Maintain a stitch density of 6 stitches per 2cm when sewing PVC reflective tape. Overstitching can weaken the tape edges, while too few stitches may compromise durability.

- Use high-quality sewing machines and smooth-edged needles designed for PVC materials to prevent accidental tearing or damage.

- Train staff to handle reflective materials properly, especially when working on intricate garment designs where stress points are likely to appear.

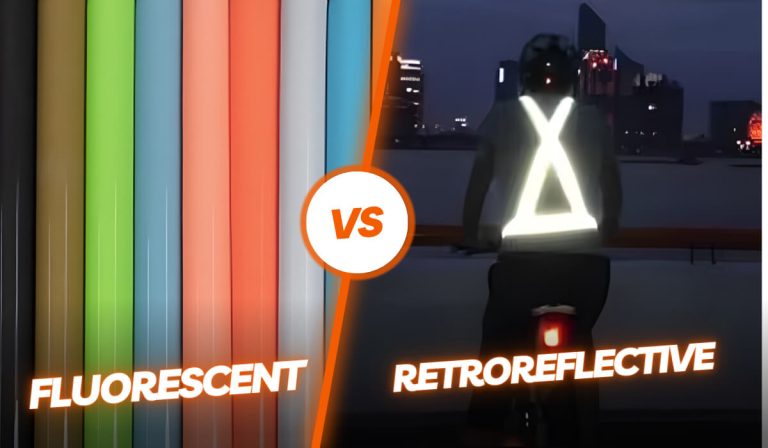

Non-compliance with safety standards (EN20471)

Reflective materials, particularly those used in safety vests or industrial clothing, must comply with strict safety standards such as EN 20471. Non-compliance with these standards could lead to product recalls, safety risks, or regulatory issues.

How to avoid it

- Verify that the reflective tape meets EN20471 standards for reflectivity, durability, and brightness. This ensures visibility in low-light conditions and compliance with safety requirements.

- Request test reports or certifications from your PVC reflective tape supplier to confirm product compliance before use.

- Perform in-house testing, including durability and reflectivity checks, to ensure the final product meets necessary standards.

Customizable printed PVC reflective tape for safety and branding

PVC reflective tape price variations based on reflectivity

The price of PVC reflective tape varies based on its reflectivity level. Higher reflectivity materials, essential for safety-critical applications, are naturally more expensive. Prices can range from USD 0.9 per meter to USD 5 per meter based on reflectivity, material thickness, and durability.

How to avoid issues here

Determine the application requirements before purchasing reflective tape. For example:

- Use basic PVC reflective tape for non-critical decorative purposes.

- Opt for higher-grade reflective tape for safety vests, traffic cones, or industrial gear requiring maximum visibility.

- Balance cost and quality by considering the specific demands of your application. Avoid overpaying for high-grade products if lower-grade ones will suffice.

Additional Tips for Better Performance

Proper storage and handling

Store PVC reflective tape in cool, dry areas away from direct sunlight to preserve its reflective qualities over time.

Avoid exposing the tape to excessive heat or humidity, as this may cause deterioration of the adhesive and reflective properties.

Regular inspections

Conduct routine quality checks during production and before shipping to ensure that no defects, such as peeling, discoloration, or breakage, are present in the reflective tape.

Application-specific considerations

- For outdoor use, select reflective tape with UV-resistant properties to avoid fading.

- For products exposed to heavy wear (e.g., industrial uniforms), opt for tape with enhanced abrasion resistance.

Conclusion

By understanding and addressing these common issues with PVC reflective tape, you can significantly improve the quality, durability, and performance of your reflective products. Whether you’re manufacturing safety vests, industrial gear, or decorative items, getting it right the first time can save you time, money, and effort.

If you want to learn more about choosing the right PVC reflective tape or need expert guidance to avoid these problems in your production process, contact us today! We provide high-quality, EN20471-compliant reflective materials tailored to your specific needs and budget. Let us help you elevate the quality and reliability of your reflective products!

Related blogs